Blog

Slitting 101: Deciding Which Method is Right for You

October 2nd, 2015

What Slitting Method is right for you? As many companies begin the process of purchasing a custom Slitter Rewinder system, they will soon come to realize that the answer to this question is imperative to the type of machine that Is designed and built specifically for the company’s application. Contech believes that focusing on our customers application parameters, while keeping cost, safety, and simplicity in mind, are important factors in choosing the right slitter for the job. Everyone knows that to save money on the bottom line, the overall converting operation needs to be studied and the slitting and rewinding procedures are the perfect place to look. Having the right machine for the job is the biggest savings a converter can have.

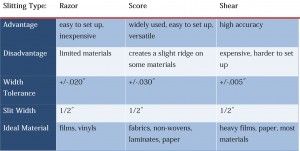

Below is a brief rundown of some of the more common slitting methods. Before you enter into purchasing a converting machine, it is best to determine which slitting method is best for your material. Some methods will cause your material to react differently and can cause frayed edges, stretched material, or other issues that are unwanted for the next step of the production process. Before starting the purchasing process, Contech highly recommends that you send us a sample of your material BEFORE the quoting process can begin. Contact us today to schedule a free material test on our in-house converting machines.

ACCORDING TO “Slitting Techniques, Choosing the Best Method,” there are three main slitting methods in use and a formula to best match the correct slitting method to the application.

The 3-step procedure is as follows: 1) Identify the important characteristics of each slitting method; 2) identify the characteristics of the material to be slit; and 3) Match the material to the best slitting method. These three slitting methods include shear slitting, crush or score slitting, and razor slitting. Each has its own set of pros and cons.

Razor Slitting: One of the most popular methods of slitting, this method utilizes a razor blade to cut material. The material is unwound from the roll, passes over the razor(s) and is cut, and gets re-wound onto the child cores. Razor slitting is frequently used to slit materials ranging from woven to non-wovens like plastics or films.

Shear slitting, Male and female circular knives are utilized to provide a cut that is similar to the same effect as scissors. This system is used widely on paper, films, foils and other no-woven materials.

Score Slitting: Also known as “crush cut slitting.” A knife is pressed and runs against a hardened anvil shaft essentially crushing the material. The system works well with hundreds of materials including non-wovens.

More questions? Call us and discuss which slitting type would be best suited for your company. Our engineers are always here to answer your questions, even if you are not sure if you are ready to purchase a machine or not, we will be happy to walk you through the decision making process.

We look forward to hearing from you. Happy slitting everyone.