Products

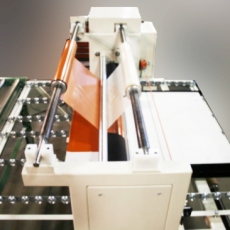

Contech Omega Squeeze Roll Aplicator (SRA) 1000 Laminator

- Hot or Cold Models Available

- Variable Speed

- Adjustable Pressure

- Web Tension Control

- Adjustable guides

- Foot Switch Control

- Options: Heat Bar Assembly, Loading Conveyor, Unloading Conveyor, Collar Roll Assembly,

- Edge Roll Assembly, Front/Rear Loading Table

Operation

Unwind Station

The basic function of the Roll Unwind Stand is to support a roll of material and provide web tension during unwind process.

The 100 lb. Roll Unwind Station provides a support system for a maximum of 100 Lbs. The material is mounted to the unwind mandrel using tapered core inserts. The material is then routed into the DigiCutter.

Unwind Brake

A material unwind brake is attached to the unwind mandrel support block. Aligning the slotted shaft on the unwind mandrel to the shaft in the Mandrel support block will interlock the material unwind mandrel with the material unwind brake.

Brake pressure is supplied to the brake by a precision regulator and gauge set. Turning the black knob clockwise will increase the pressure, while, turning the knob counterclockwise will decrease the pressure applied to the air brake.

Drive Roller

The Drive Roller is the roller that increments and measures the material. Roller position is provided to the control computer by an encoder attached to the Increment Drive Shaft. Acceleration, deceleration and, length information is calculated by the computer which, controls the DC drive card, powering the Increment Roller.

Cutter Blade

The Cutter Blade is the circular blade that travels the width of the machine, performing the cutting action.

The cutting system uses a pneumatic cylinder to provide blade movement. To perform a single cut, the pneumatic cylinder must travel the complete width of the machine. During the cut cycle, the blade is pushed from one end of the Cutter Head Support Tube to the other. An electrically activated 3-position 5-way pneumatic control valve directs the airflow into the cylinder. Located on the exhaust ports of the valve are adjustable flow mufflers that restrict the flow of air out of the cylinder. By restricting exhaust air of the cylinder, speed and force of the blade can be maintained throughout the entire cut cycle. Internally, a piston is forced back and fourth through the cylinder by airflow supplied by the control valve. Air is forced into opposite ends to move different directions. Limit Switches are mounted above the Cutter Head to provide position sensing. Two switches are used in the unit to provide end-of-travel limits for the actuator.

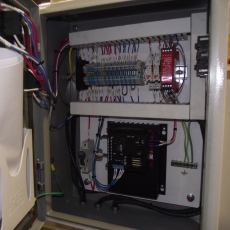

The coils are operated by 24-VDC outputs supplied at the I/O board. The electric valve operates by moving an internal spool that redirects airflow. The spool operates in one of three positions: left, center, and right. When a coil is activated, the spool is pushed into position and airflow is directed to the cylinder expelling the return air from the cylinder and driving the cutting blade.

Nip Roller

The Nip Roller is a movable roller used to keep the material in contact with the Drive Roller. The roller may be placed into the open position, allowing more access for material loading.

Nip Roller Control

Placing the Nip Roller Open /Close switch in the Open (up) position will raise the Nip Roller to the full up position. Placing the switch in the Close (down) position will lower the Nip Roller. Nip Roller pressure is controlled by the pneumatic gauge and regulator set, turning the black knob labeled Nip Pressure will increase the pressure applied to the cylinders in the down position. Turning the knob counterclockwise will decrease the pressure.

Note:

Excessive nip pressure may temporarily bow the nip roller.

Static Eliminator

The static eliminator option will reduce the effects of electrostatic charges generated with some materials. The eliminator consists of two parts. The control box, mounted inside the right sheet metal cover, generates the high voltage source required to reduce the static charge. The second component is a Hot-Bar located under the front guard near the top cutting blade. An ON/OFF switch is located on the Static Eliminator power supply.