Products

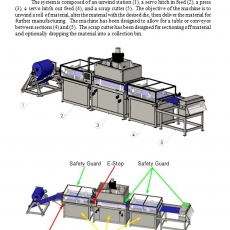

Dual Hitch Feed Web Press

This Hitch Feed is designed to attach to a Hitch Feed Press. The system is a Servo conveyor belt, and the input side and the output side run in unison.

The material is clamped to the belt while it is moving so that multiple layers can be run together. Because input and output run in unison, there is no tension applied to the material keeping parts from coming out of the web while the press in engaged. Different types of unwinds can be used for feeding material into machine.

INFEED UNWINDS

Gravity loop, fed into the press by a dual powered unwinds. Design to be cantilevered style. The position of this loop will control the operation of the increment system and press. Material will be stored in the loop to complete at least one full cycle of the press. Mechanical y axis in-feed guides to the entrance of the hitch feed increment module. One unwind operational while the opposite unwind is disabled for loading. Switching provided to toggle between unwinds.

HITCH FEED PRESS

Press has dual input and output belt/hitch feed systems that increments the material into the press as well as the exit side. Die cut parts will progress through the press to an operator removal area. Press is a three plate type, 150 ton. Hydraulic pump will be electronic proportional control to increase speed and response time.

Press is supplied including structural tubing steel frame, self-contained electronic controlled hydraulic power unit with touch screen controls, adjustable stroke length, dwell timer, single automatic sheet counter, hour meter, and self-diagnostic safety interlock system. Die cut area within the press will have an internal web clamp system to flatten the web prior to die cutting.

FOUR CORNER STOP BLOCKS

Four corner stop blocks are included. This feature provides precise control of the stopping position of the upper platen during the cutting cycle. Allows adjustment of cutting depth front to back, side to side, or one corner only. The press plate is designed so as these deflections will never permanently bend it. The stop blocks are adjustable in

metric increments

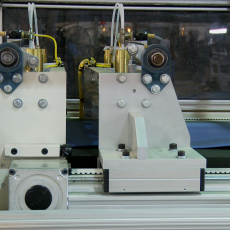

DUAL HITCH FEED INCREMENT SYSTEM

Hitch feed system is a clamp system that clamps the material to the servo controlled increment belt and is servo driven on linear slides to increment material accurately into press cavity. The exit system is slaved to the input hitch feed system to mimic its motion. There are many performance advantages offered by the servo motor systems. Has very accurate positioning. The motor has excellent low-end torque, allowing it to accelerate and decelerate very quickly. This characteristic is important for our system since we stop to cut and require accurate increments. Internal feedback from the motor is used to establish the increment distance. Scaling factors are used to convert the length entry into motor pulses.CONTROLS

Allen Bradley system with touch screen control for the complete system will be mounted on a separate swing arm console located near the web entrance area on the press. The system is PLC controlled with all programming done in our plant. Ability to adjust speed, length of increment, dwell time, setup mode and/or web mode. Self-diagnostics are included in the control.

SPECIFICATIONS

Incoming Web (Unwinds)

Maximum web width: 720mm core air shafts Easy inflate/deflate shafts with rotary couplings and switch 500 kg. max weight each unwind 900 mm max O.D. Gravity input with optic for accumulation and unwind control Dual cantilevered Switch between unwinds for disable and enable for loading or running

Press

3 plate type press, size: 720mm web width x 500mm increment 150 ton Common board die & Bolster pneumatic clamp 4 corner stop block system Maximum material size: web: 720mm Controls on separate console located at press

Increment System

Allen Bradley with servo drive (Compac Logix Format) Contech to do all programming Touch screen controls Blind increment In-feed mechanical guides for y axis

Tolerances

Tolerance +/- .006 in X axis Mechanically guided Y axis

Misc. Features

Vacuum Plenum with vacuum connection Wiring and software for customer supplied safety blocks

Cycle rate.

3 meters per min. Increment range from .25 meter to .5 meter

Utilities

Electrical: 480 Volts, 60 Cycle, 3 Phase (other voltage upon request) Air: 90 psi clean, dry air