Blog

The Evolution Of The Contech Custom Machine

September 23rd, 2015

This month was National Inventors Month, so we felt it fitting to take you through the evolutionary process of our custom machines. From the Invention to Installation, this will give you a glimpse of what our team of brilliant engineers, attentive salesmen and skilled craftsmen put into every design to bring it to reality.

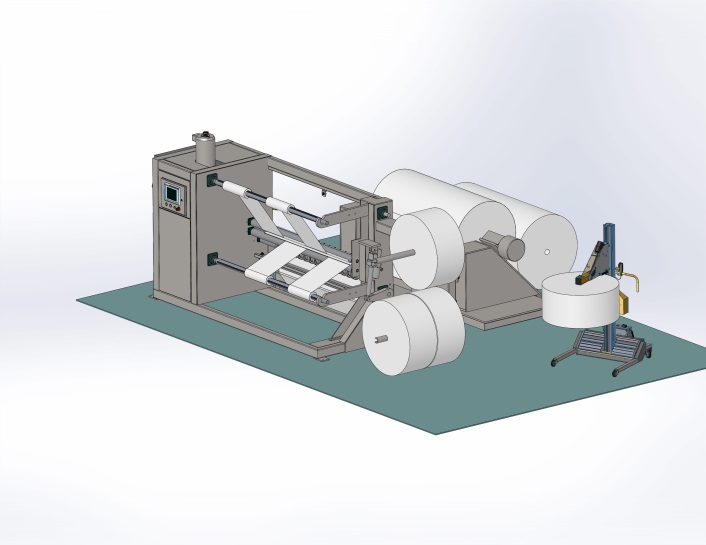

As custom machine builders, Contech understands that creating a machine from concept stage requires extensive knowledge of machine components and capabilities. Contech is an experienced design/build firm that is skilled at proving functionality at critical points in the machine development process. Contech is (and has been) using multi axis servo technology to control complex motion in custom converting equipment. 21st century touchscreen control panels, programmable controllers, and ‘motion control over Ethernet’ devices are assembled and programmed into solutions that allow precise and coordinated component movements. Another benefit to using servo technology is the ease of commissioning new machinery. Parameters can be adjusted or motion profiles adjusted to match what the material will bear. Machinery solutions can go from concept to reality quickly with our Mechatronics approach. All machines from the smallest to the largest are computer modeled and simulated prior to manufacturing. Alternative competing concepts can also be explored and evaluated.

We complete the following steps for every machine

Phase 1: Concept

Every project starts with a base level concept with varying degrees of detail. From napkin drawing to fully developed machine spec, we take your concept and make it a reality. At this stage of the process our Sales Engineer will help you:

- Evaluate the feasibility of your project

- Provide candid feedback on your concept

- Propose alternative conceptual solutions

- 3D CAD concept models are developed and offered to the customer

- Mechanical features are fully articulated and explored

- Adjustments and changes are discussed and approved

- Control architecture, interfaces, and safety devices are decided upon

Phase 2: Front end engineering, estimating, and quoting

This is the most critical stage of any project we are involved with. At this step we work diligently to fully extract your project requirements & specifications. Our engineers do the due-diligence up front to identify:

- How the machine will work by providing a fully developed concept & preliminary drawing.

- How long it will take to build your machine by providing a timeline that you can count on.

- How much it will cost by providing a precise and accurate quote.

- A quote is generated based upon the developments of the above

- Equipment options can be listed separately if desired

- Delivery time, terms, warranty, and shipment methods are listed

Phase 3: Machine Design

The Engineers design builds upon the concept and Front end stages of the project by integrating the details that constitute a final machine design. Included in this phase are:

- Ballooned assembly drawings are developed and shared for approval

- Electrical drawings are then developed and shared for approval

- Status photos, periodic online meetings, and customer visits are encouraged

- An operators manual and support documents are created

Phase 4: Machine Automation

The same engineer who worked with you on the design stage of the project will also program the controls and automate your custom application. In the automation phase of your project our custom machine builders will:

- Determine overall automation design & strategy

- Complete electrical design

- Determine best operating platform for the application

- Complete programming and operator interface

- Data collection

Phase 5: Machine Fabrication

Your machine will then be fabricated by our skilled craftsmen at our in-house fabrication facility. This stage includes:

- Structural fabrication

- Fully equipped machine shop

- Mechanical fabrication

- Electrical wiring

- Piping/tubing

- Instrumentation

- Component assembly

- Finishing

Phase 6: Signoff/ Training/ Delivery/ Installation

As custom machine manufacturers, the machines that leave our facility are fully tested while operating at required specifications. We welcome our clients to our facility to be an integral part of this process. Our start-up and commissioning process includes:

- Operator training

- Maintenance training

- Shipping

- On-site integration and Installation

- The machine is tested and approved prior to shipment

- Installation help and assistance is offered; can be mechanical, electrical or both

- Arrangements can be made for specialized delivery to minimize chance of damage

Your project is not complete until your machine is running as specified, your staff is fully trained and all issues are resolved.

We Put So Much of Ourselves Into Each & Every Machine We Build, Sometimes It Is a Little Hard To Say Goodbye.