Products

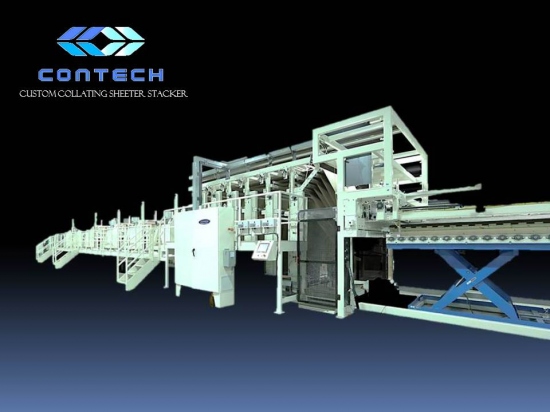

Contech Collating Sheeter Stacker

The Contech Collating Sheeter Stacker is a marvel of efficiency: it is specially designed to handle heavy-duty work loads.

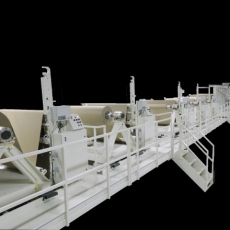

This machine utilizes a series of heavy duty A frame unwinds with a dedicated accumulator for the web path located at the front of each unwind. The industrial Servo Sheeter has a steel box frame, down-acting custom cutting blades and blade holding assembly, sheet metal covers, and safety systems where required.

The Contech Collating Sheeter Stacker is customizable to your specifications.

Featured in this model are:

1.0 Powered Unwinds

Heavy duty Powered A frame unwinds using steel tube framing, electronic sensor, sensing roll diameter for unwinds, a(150mm) air shaft and safety chuck on both ends of the drop in style shaft. A dedicated accumulator for each web path located in front of all unwinds. PID control to control between accumulators and VFD powered unwinds to pay off the web from each unwind. End of roll sensor, splice station, and operators platform with safety rails to access unwind controls and splice station. The PID on each of the accumulators will control the web tension and speed on each of the unwinds automatically. An automatic edge guide and E-stop will be mounted on each unwind. An additional 3 web guides between the accumulator and sheeter nip set for the back 3 unwinds, due to the distance from the sheeter nip set is also included.

2.0 Sheeter

Industrial Servo Sheeter has been figured using a boxed steel frame, down-acting custom cutting blades and blade holding assembly, sheet metal covers and interlocked safety system where required. Dual axis servo driven increment nip set system.

Heavy-duty air bias nip roller has been figured. Power for the cutting blade assembly is an electric motor, gearbox and air clutch assembly. Stationary horizontal blade with a multi axis cut action and horizontal moving blade set at an angle to give a clean cut.

For multi-layer webs the system is designed to maintain a separate web path for each web until it enters into the increment nip set.

3.0 Increment System

Increment system contains dual axis servo nip set system.

4.0 Controls

Telemechanique Controls Platform:

Operator functions and diagnostic information will be displayed from main HMI.

5.0 Tolerance

Standard repeat-ability of cut to length tolerance of +/- .035 on single layer webs. Note the various thicknesses will change the setting that you must set in the PLC but you will have the repeat-ability. This is based upon stable materials. 6 layers of web could increase the tolerance.

6.0 Testing

Purchaser will furnish materials for testing and for approval in our plant.

7.0 Stacker

Dual gripper stacker consisting of the tube frame, gripper assembly complete with traveling clamp, timing belt drive with pulleys, sensors and guards for the system, auto decremented scissor lift, dual Servo drive motor and gear assembly to power the dual gripper and the controls necessary to operate the unit. We have included for safety purposes sheet metal spacers between the rollers for an operator to walk on the first row of rollers on the entrance side of the pallet handling system.

Operation of the stacker

Sheeter will advance the web out from the cutting blades about 6 and stop, secondary traveling clamp will grip the end of the sheet, sheeter drive and the clamp drive will move the web out until it meets and matches up with the stacking gripper. Gripper will then pull the sheet out farther above the stacking tray drop the sheet in position and return to home position. While the stacking gripper is moving the sheet out to the proper position the traveling clamp moves back to the blade area to pick up the next sheet. The auto decrementing tray will keep the distance between the gripper bar and the top of the stack monitored. When the set number of sheets has been stacked, the unit will stop and automatically remove the full pallet and the operator will replace with an empty pallet. Operator will command a restart and machine will return to home position and resume cycle.

Also figured is a system of speeding up the process concerning changing the stack pallet. When the stack has been completed, as set in the PLC, the tray will be moved out away from the stack 90 degrees from the web. The operator will install an empty pallet, command a resume operation and the machine will automatically move to home position and the cycle will start up again. When the stack has been completed the process will repeat. Exit conveyor will hold 1 full pallet. The operator must also remove the pallet that has the stack on it. Common size pallets must be used for this system to function.

System will have a custom feature that the operator can control through the PLC to stack stagger sheets 1 to 2 in front or back of each other in the direction of the web movement.

8.0 Specifications

8.1 Unwind (6ea.)

Maximum web width 67 (1.7m) minimum web width 24 (.62m)

Heavy duty A frame

6 aluminum unwind air chucks with special square ends on the shaft to match the safety chucks.

Maximum weight 6600 lbs.(3000kg)

Maximum diameter 64 (1.6m)

Accumulators in front of all the unwinds with a dual loop PID sensors to control the tension and speed of unwinds.

Auto edge guide for each of the unwinds as well as on accumulators for unwinds 4, 5 and 6.

Boschert P 50 chucks and 6 airshafts.

One E-stop and an end of roll sensor included.

Manually operated splice station has been included.

Walkway in front of the unwind next to the splice station.

Railing around the unwinds as on machine

Powered arms to pick up the empty roll shaft at each unwind to help on change over time.

6 station accumulators complete with sensors and air tension controls.

6 air clamps to clamp webs at the accumulators.

Single screen control on the unwinds at the location of the main controls.

.2 Sheeter

6(1.7m) maximum width web for sheeter

Heavy duty Servo sheeter frame, sheet metal and interlocked safety guards.

Dual Servo increment system.

Electric motor driven gearbox and electric clutch on cutting blade.

Down acting cutting blades (custom grind) 69 wide blades.

Air bias, rubber nip roller (servo driven), on the 6 drive roller.

One E-stop.

Large diameter drive roller.

.3 Increment System

Dual axis Servo (powered nip and drive roller).

6 hard rubber drive roller.

.4 Controls

Telemechanique control platform

8.5 Utilities

Electrical 380 volts, 50 cycle, 3 phase

All parts CE marked

Air 90 psi clean and dry air

8.6 Stacker

Maximum web of 67 (1.7m) minimum web 24(.62m)

Dual gripper type stacker

Dual servo operated unit, one for each gripper

Maximum sheet length of 172 (4.370m) minimum sheet length 24(.62m)

Stacker tolerance single land /- ½. (/- 12mm)

Maximum stack height 40(1m)

Decrementing table to stack on

Two E-Stops

Mechanical pallet removal system as well as positioning empty pallet.

Operator places empty pallet in storage rack and removes pallet with stack on it.

One pallet rack on exit side of the machine 90 degrees from the web.

8.7 Misc.

Machine construction to disassemble to fit Ocean containers

9.0 Documentation

Standard documentation package includes the Operation Manual. Manual will contain the information necessary to operate the equipment. Description of operating procedures, control functions, and basic operating theories will be included as well as maintenance information.

Ladder diagrams, electrical schematics, and source code will be furnished.

Source code to be supplied in English and French

Interested? Contact us for a quote.